The CVT Guides are used to separate the CVT Assembly from the engine.

They are steel rods that bolt onto the engine and help hold the CVT up as it is separated from the engine.

09920-31050 CVT Guide 09920-31050 CVT Guide

You can purchase the OEM CVT Guides from any OEM parts vendor.

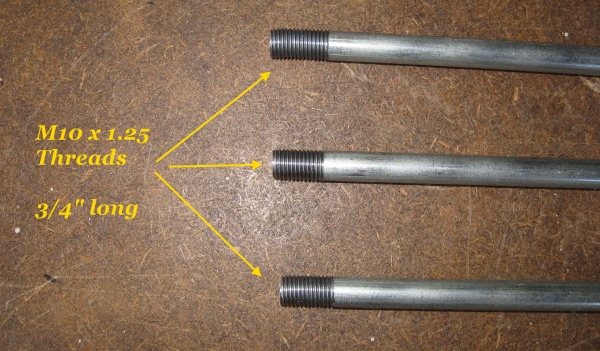

The dimensions of the Guides are as follows: M10 x 1.25 x 30 cm or M10 x 1.25 x 12 inches

You can try and purchase metric bolts with that match the CVT Guide dimensions. They will need to be at least 10” long.

Another option is to fabricate your own from steel rods and use a die/tap tool to cut the proper threads.

I opted to fabricate my own, as I could not locally locate any bolts long enough to be useful. It was also a lot cheaper to just buy a 3 feet long ⅜” steel rod for $5.00, cut it into three 12 inch rods and thread one end on each rod.

You will need a threading tool to make your own so keep than in mind as far as cost is concerned

Another alternative is to use the Engine Mounting Bolts that came off the scoot during the engine / frame separation. I chose not to use those as I did not want to run the risk of bending them and have to pay Suzuki prices to replace them.

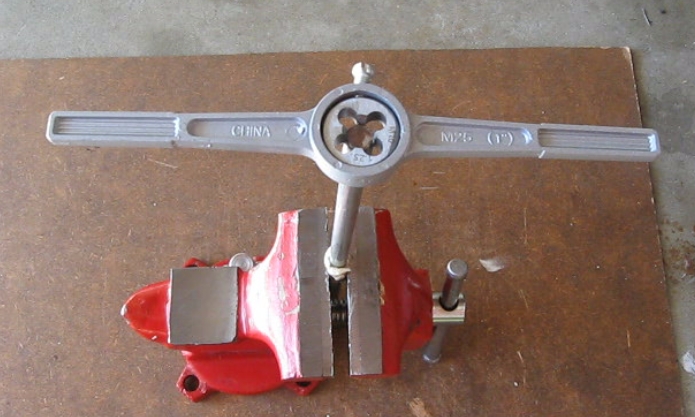

I purchased a Tap & Die set from Harbor Freight for $12.00 on sale which had an M10 x 1.25 cutting tool and a thread pitch gauge.

Here is my tools list for fabricating your own CVT Guides:

Materials |

- 3 feet long 10 mm or ⅜” steel rod

- Cutting oil or generic oil/lube

| Tools |

- Threading / Cutting Tool M10 x 1.25

- Thread Gauge

- Vise

|

Step | Guides Fabrication | 1. | Cut the steel rod into three 12 inches long rods.

| 2. | Clamp a cut rod inside a vise. Make sure that the rod cannot move inside the vise.

| 3. | Assemble your threading tool.

| 4. | Oil the top of the rod inside the vise. Place the cutting tool over the rod and being threading.

I found that small cuts were the best way to proceed. Two tugs forward and one back to clear the shavings.

Use plenty of cutting oil/lube after a few strokes.

Lay a ¾ inch thread at one of the rod.

| 5. | Repeat steps 1-4 for the other two rods. | Tip: | I used an M10 x 1.25 nut to make sure that each threaded rod could thread on and off flawlessly. Also double check for any loose play, there shouldn’t be any. |

|